Wire and Cable Ends

Crimping and more . . .

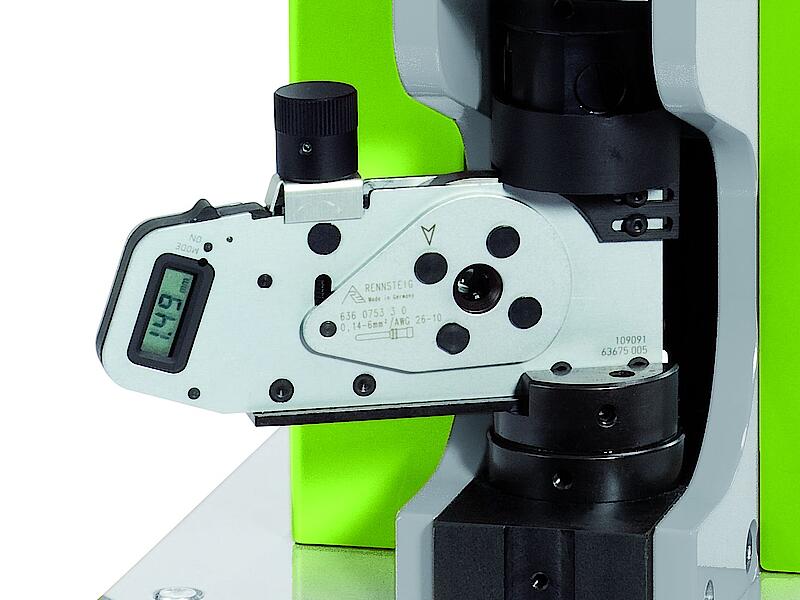

Loose Piece Terminals and Reeled Terminals

Affixing various crimp terminals to ensure precise and secure connections and optimized functionality.

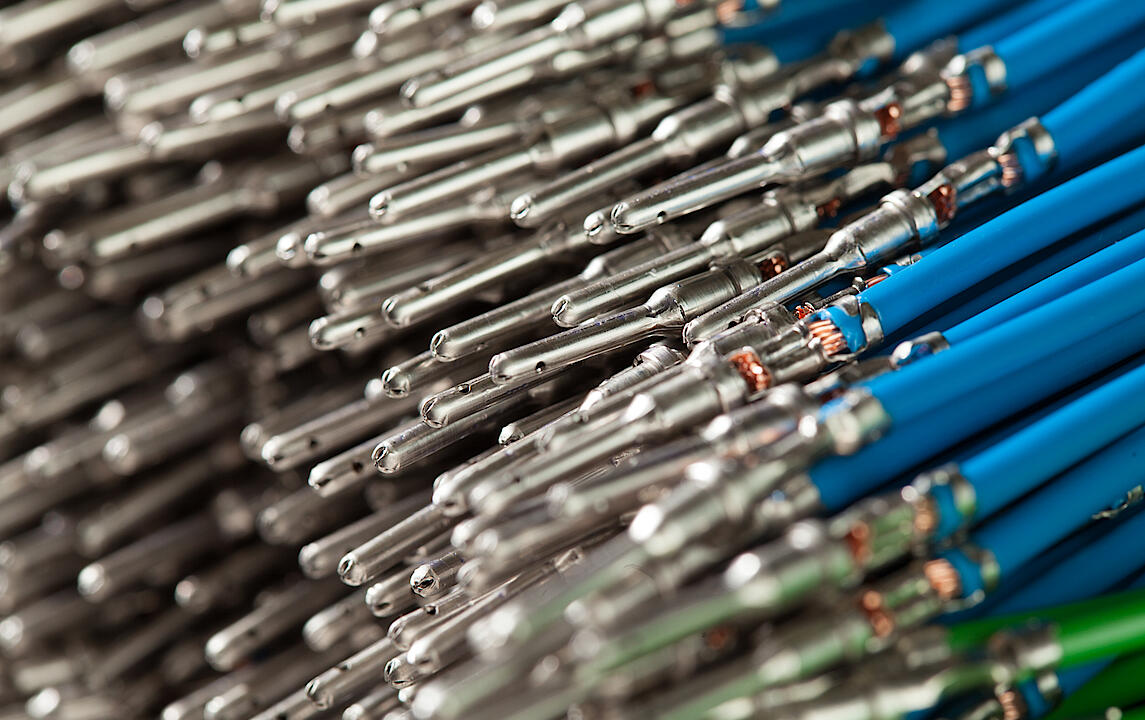

Turned Contacts and Wire End Ferrules

Crimping of turned pin and socket contacts, also for jacketed cables.

Sealed Terminals

Affixing seals to provide permanent protection from dirt and moisture.

Double-Crimp Connections

Production of various cable combinations using the double crimping process with identical and different cross-sections and colours.

Tin-Plated Wire Ends

Lead-free tin-plating of wire ends using the dipping and wave technology to protect the single strands from damage and to facilitate further processing.

Compacted Wire Ends

Manufacturing of reliable electromechanical connections by compacting strands using resistance welding.

Special/ Patented Processes for Compacted Strands

Affixing insulation grips on ultra-fine stranded wires for reinforcement and protection against insulation shifting.