If you want to learn more about plastics engineering, you’re in the right place. This section provides you with definitions of frequently used terms and useful tools.

Useful Tools

Delivery Time Calculator

Would you like to know when you order will be delivered?

Just choose the order date and the calculator will automatically show the delivery date. Alternatively, you can enter the dates manually or drag the handle in the calculator.

Definitions and Explanations

Frequently Used Technical Terms

Here you can learn more about technical terms and processes involved in assembling wires and cables.

A

A wire gauge is a measurement of a wire’s diameter. The American Wire Gauge is a standardized wire gauge system. It is based on the number of drawing operations used to produce a given gauge of wire.

This particular cable conductor size is based on the AWG standard. It is mainly used in the United States. The smaller the AWG-number the larger the wire’s diameter.

B

Blank plugs are used for housings in which not all pins are plugged in. They prevent dirt and water from getting into the non-contacted parts of the housing.

The bending radius indicates the extent to which a cable can be bent without damaging it. It can be calculated by multiplying the outer cable diameter with a cable multiplier. The latter depends on the cable type. Exceeding the bending radius may compromise the conductivity or cause a cable break.

C

Cable assembly generally refers to the production of cables, cable bundles or cable harnesses that are ready for connection.

A cable harness is a bundle consisting of various wires.

A cable jacket is the outer/external coat of a sheathed cable.

Copper is a malleable, ductile and soft metal. Because of its very high thermal and electrical conductivity it is used for electrical cables.

The term 'copper basis' indicates the base/standard price for copper that is included in the overall price. In line with the industry standards, the copper basis is 150,00€/100kg.

The additional amount of copper that is added to the base/standard price. It is commonly measured as €/km for cables and €/100 units for cable sets. It is common practice to use the invoice date as the basis for calculating the copper surcharge.

The copper surcharge can be calculated with the following formula:

Copper surcharge (EUR/km) = copper value (kg/km) x (((DEL rate [EUR/kg] +1% delivery charge) – copper basis [EUR/kg]))/100)

The copper value constitutes the weight of the copper used in cables or stranded wires. It is indicated either in kg/km or kg/m.

The term 'core' (or cable core) refers to the stranded wires that are connected in a sheathed cable.

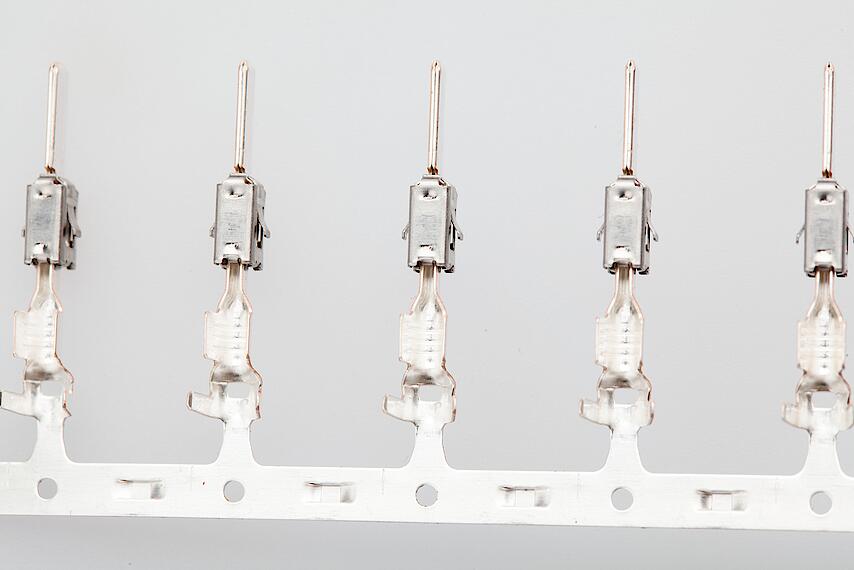

Crimping constitutes a process in which two components are joined by being deformed mechanically. This can be done through beading, squeezing, coiling or folding.

In the industrial production of wires, crimp connections have largely replaced soldered joints. What makes them stand out is their high mechanical and thermal load capacity. The latter depends on choosing the right material, fitting contacts and technical processing. Therefore, there is a wide range of crimp contacts and crimping tools.

One generally distinguishes between two types of crimps: open and closed ones.

In closed-barrel crimps, the insulated stranded wired is inserted and squeezed into a barrel. The opening of the connector has to be squeezed tightly against the stranded wire. Commonly used barrels are wire end ferrules, turned contacts as well as partly and fully insulated crimp barrels.

Open-barrel crimps are produced on reels and are mechanically processed. During the crimping process, the u-shaped open crimp barrel is closed and folds around the electrical conductor (conductor crimp). The insulation also mostly gets crimped (insulation crimp).

The cross-sectional area of a cable is the area of the strand and is measured in mm².

Cutting to length refers to cutting a cable to a particular length so that it can be processed further or sold on demand.

D

'DIN' is the acronym for the most important German organization for standardization, the German Institute for Standardization, which sets uniform, voluntary standards.

DIN standards can be recognized on a national, European or international level.

If further letters are added to the acronym, they usually imply that an existing norm was integrated into the DIN standard. The letter also indicates the origin and the area in which the standard is applied.

For example:

EN: European standards created by the European Committee for Standardization (CEN), the European Committee for Electrotechnical Standardization (CENELEC) or the European Telecommunications Institute (ETSI).

ISO: International rules set by the International Organization for Standardization.

IEC: Standards set by the International Electrotechnical Commission.

E

Elastomers are elastically mouldable plastics, which change shape by pressure loading, but afterwards they go back to their original shape. They are commonly used for seals and tyres.

See 'elastomers'.

H

See 'plug housing'.

I

IEC is the abbreviation for the International Electrotechnical Commission, a non-profit organization that develops standards for electrical, electronic and related technologies. The IEC is headquartered in Geneva, Switzerland.

The term insulation refers to the external sheathing of a stranded wire. Its purpose is two-fold: on the one hand, it serves as a protective coat; on the other hand, it prevents the transfer of electric currents.

Examples:

Polytetrafluoroethylene such asPolytetrafluoroethylene such as

| Abbreviation | Material |

|---|---|

| PVC | Polyvinyl Chloride |

| TPE | Polyether Elastomer (thermoplastic elastomer) |

| PTFE | Polytetrafluoroethylene such as Teflon ® |

| SIR | Silicone Rubber |

The International Organization for Standardization (ISO) represents a union of various international standards organizations. It sets standards for all areas except for electrical and electronic technologies. Standards for the latter two areas are developed by the IEC.

The ISO/TS 16949 is the most significant standard for European and Northern American automotive industries. It is based on the EN ISO 9001 and provides quality management systems for companies working in this sector. The letters ‘TS’ stand for ‘technical specification’.

P

Plastic is the general term for a wide range of synthetic or semi-synthetic materials that show characteristics such as elasticity, hardness, thermal stability and heat stability. Depending on their components, they can be used for a very wide range of applications.

The three main groups of plastics are thermoplastics, thermosets and elastomers.

In the manufacturing of plastics, the term ‘plasticization’ refers to the process of changing the structure of a polymer so that it becomes elastic/malleable. Granules or powder is plasticized through heating. In a further step, the elastic material can be turned into injection-moulded components.

The plug housing is used to contact mating connectors. There are different types of plug housings depending on the number of poles, the number of slots and the general make-up of the housings. With regard to their make-up they, for instance, differ in their locking, seals and the material they are made of.

T

The tensile strength is the force required to pull the wire apart from each end. It is an indicator of the mechanical load capacity of a crimp connection.

Thermoplastics represent a group of plastics that become mouldable when heated. This process can be repeated as often as it is required. Apart from that, thermoplastics can also be welded.

Thermosets or thermosetting polymers belong to the three main types of plastics. Once they have been completely solidified in a thermosetting process (a chemical reaction), they are very hard. Once they have been solidified, they cannot be shaped again.

See ‘thermosets'.

S

See 'single wire seal'.

A sheathed cable consists of several cable cores. The insulated wires (stranded wires) are bundled and then held together by insulating coat/sheath or cable jacket.

Sheathed cables can either be shielded or unshielded. Shielded cables are additionally covered with a sheathing (consisting of suitable materials) that protects them from electric or magnetic fields.

Single wire seals (or simply ‘seals’) protect the wire from dirt and moisture. They are usually held in place by the insulation crimp.

A coloured label that indicates the composition and applications of electrical cables as well as other important information. The labels are printed with the help of special ink-jet or laser printers.

The strand (also called electrical conductor) consists of multiple single copper wires and bundles of copper wires that are arranged helically. In some cases, strands can also be made of aluminium or other suitable alloys. The conductor transfers electrical energy or signals. The cross section or cross-sectional area of the strand has to be matched with the electric current density.

In electrical engineering, stranded wires usually consist of thin, flexible single wires that are covered with an insulating sheathing. They can be divided into two groups, namely finely and super-finely stranded wires. The two groups differ from each other with regard to the general cable composition and the number of single wires. Inflexible single-wire cables are also defined as stranded wires.

Stripping refers to removing the outer sheath – the so-called cable jacket – from a single wire or sheathed cables without damaging the elements underneath. This is achieved by the help of specific pliers and knives.

Strapping is a step during the cable assembly in which stranded wires are wrapped with tapes so that several stranded wires can be tied into one unit. The wires are strapped helically, usually with PVC or textile tapes. Strapping can be done either manually or with specific strapping machines.

W

Removing the insulation from a stranded wire is called wire stripping. When removing the insulation manually, you use specific pliers (wire stripper) as the conductor or wire must not be damaged or cut. Semi- or fully-automatic processing uses special knives.

Would you like to know more?

If you have any more specific questions, we’re happy to tell you more. Feel free to get in touch with us.